Copper panels evolve and weather to a rich patina, adding beauty and depth to any building façade. Zinc panels offer an elegant matte patina. Titanium and stainless steel panels convey an image of high-tech sophistication like nothing else. Our natural metal finishes deliver the opulence of genuine metal at a fraction of the weight and cost of solid sheet alternatives.

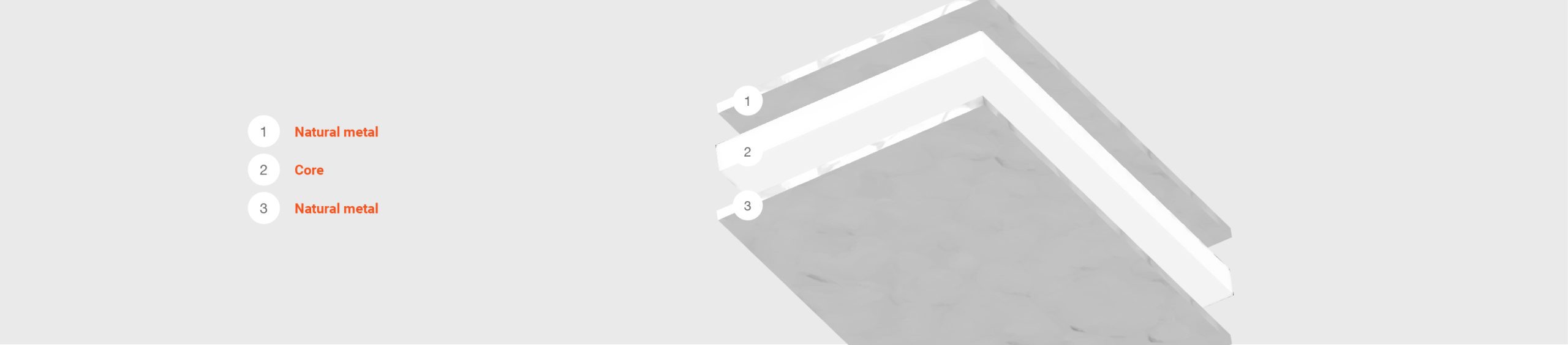

About Natural Metal Finishes

We bond metal skins to our polyethylene (PE) or fire-resistant (fr) core material to create a truly natural metal finish. The result is an MCM panel with all the beauty of sheet metal – and none of the drawbacks. Natural metal MCM is lighter in weight, more versatile, easier to fabricate and designed to remain flat and stable throughout the days, seasons and decades of any climate.

Natural Metal Finish Applications

MCM in a natural metal finish is an ideal material for exterior building cladding, entryways, canopies, soffit, fascia and more. Please contact Customer Service for current available stock and additional information.

Revere/ALPOLIC® Copper Composite Material (CCM)

Copper panel skins bonded to both sides of a fire-resistant core. Also available with a PE polyethylene core as a custom order. Natural copper finishes are often desired for the richly variable patina they gain over time.

ALPOLIC® Zinc Composite Material (ZCM)

Fire-resistant (fr) composite material with the elegant matte patina of weathered zinc panels – finished by our partner VMZINC using their QUARTZ-ZINC process. Natural zinc finishes blend well with many building materials and designs, both traditional and contemporary.

ALPOLIC® Stainless Steel Composite Material (SCM)

ALPOLIC® Titanium Composite Material (TCM)

Fire-resistant (fr) composite material with natural titanium or stainless steel panel skins. These affordable panels are strong, lightweight, versatile and easier to fabricate than solid sheet metal.

Available in these colors

Explore The Possibilities With ALPOLIC

Discover the ALPOLIC difference in the quality of our materials and endless color options. The next step in realizing your dream project begins right here.