Our Company Milestones

Our state-of-the-art manufacturing facility in Chesapeake, Virginia opens and begins production of 3mm/4mm/6mm MCM panels. The dedication ceremony for the plant is held on October 18, 1991.

The first order of 4mm MCM panels are produced and shipped. Testing on 6mm MCM panels began this same year.

ALPOLIC begins production of ALPOLIC®/fr MCM after installation of new equipment.

ALPOLIC®/fr is one of the most advanced fire-resistant materials available and is compliant with many fire codes worldwide. Offered in an extensive choice of attractive options, this affordable material is one of the most popular choices for exterior fire-resistant cladding, seen in many landmark projects around the globe.

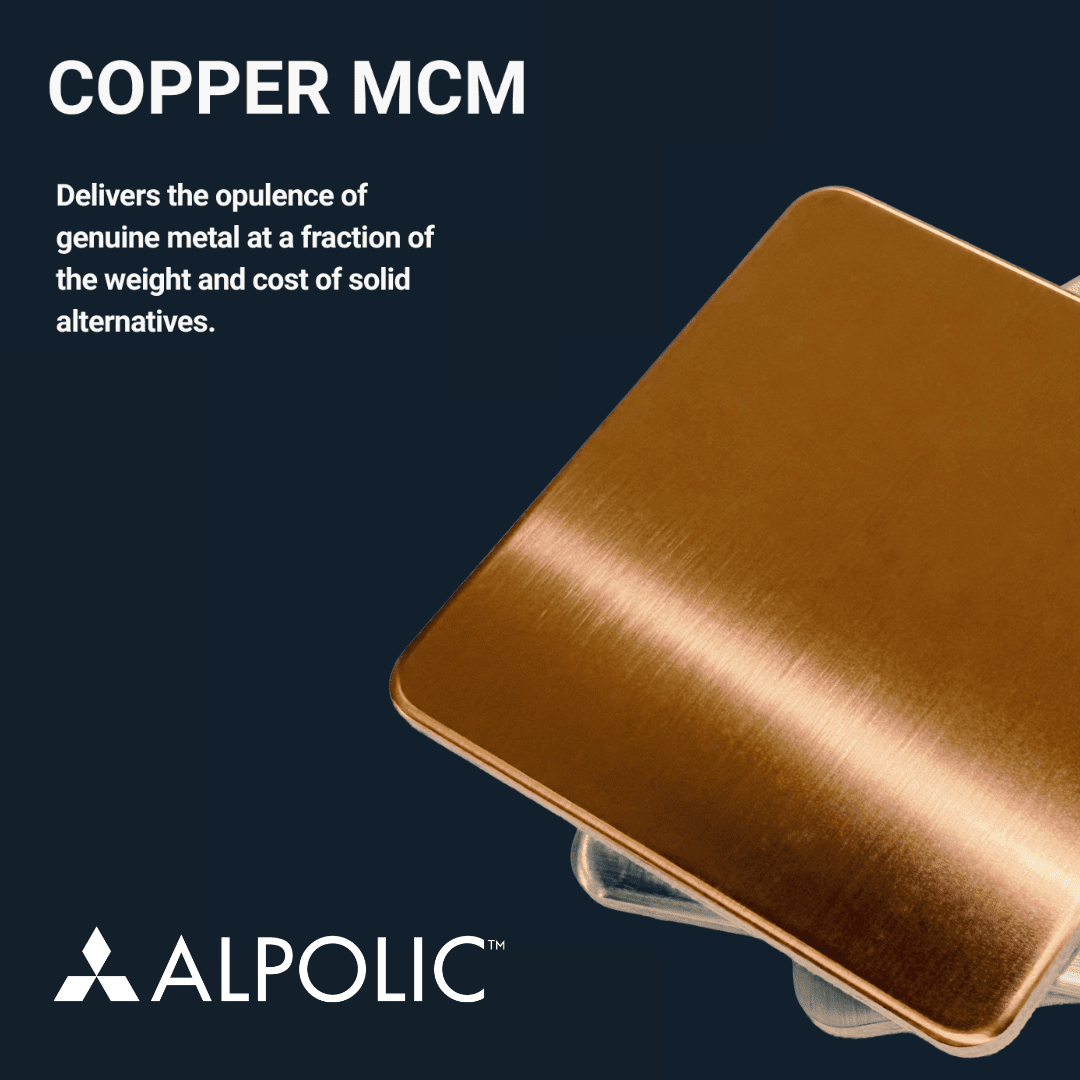

ALPOLIC sells and ships its first order of Copper Composite Materials (CCM) in the United States.

Natural metal MCM is lighter in weight, more versatile, easier to fabricate and designed to remain flat and stable throughout the days, seasons and decades of any climate. Titanium Composite Material (TCM). Stainless Steel Composite Material (SCM).

First US sale of brake metal. ALPOLIC® Brake Metal offers a complement to our Aluminum Composite Material products, giving fabricators the ability to form roof caps, flashing, fascia trim, accents and other complex forms using a sheet metal brake.

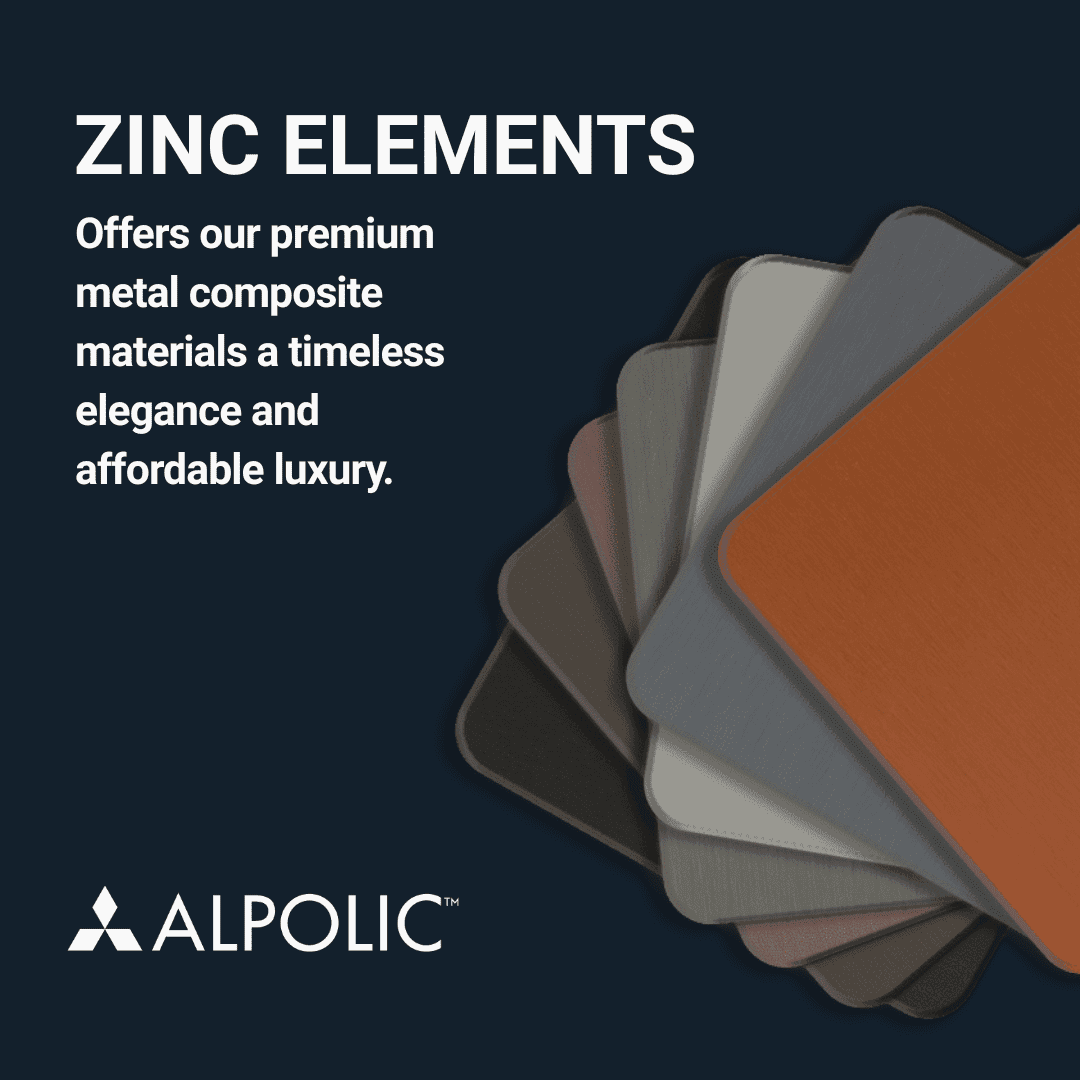

First US sale of Zinc (ZCM).

The ALPOLIC Zinc Elements Series offers our premium metal composite materials a timeless elegance and affordable luxury.

Operation Encore is ALPOLIC’s in-house recycling program for end-of-life materials also makes way for a variety of community and nonprofit projects.

ALPOLIC Americas undergoes a 22,000 square-foot warehouse expansion. First US sale of RF.

Established MFE, a new line for ALPOLIC in Wiesbaden, Hessen, Germany for expanded production and sales in the European and Central Asian markets.

First US sale of Heavy Duty (HD) MCM

ALPOLIC® Anodized MCM is introduced.

Anodized MCM can transform your next design into a legacy showpiece. Anodized aluminum is an exceptionally strong surface that brings a smooth sheen to your next project, be it a high-end residence, boutique hotel or stylish automotive dealership.

Advancements in our image transfer process expanded the Timber Series, which provides the natural look of wood, without the weight, maintenance difficulties or expense.

In partnership with VMZINC®, ALPOLIC is the first to market with a pigmented zinc composite. The PIGMENTO® Series expands our offerings of Zinc composite materials include red, blue, brown, grey and orange colors in addition to the original unfinished, natural metal QUARTZ-ZINC®

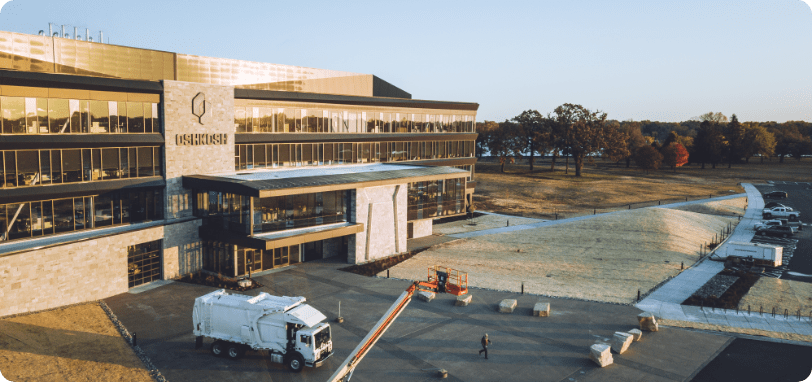

A $5 million expansion adds 40,000 square feet to increase the company’s storage, shipping and receiving capabilities. This is the second major expansion for the company, which has maintained its headquarters in the flourishing Greenbrier business district for more than 27 years. The first, a 22,000- square-foot warehouse expansion, was completed in 2013.

The new 11,000 square foot administration building opens. Featured on the envelope are three ALPOLIC finishes, including our Rusted Steel.

Mitsubishi Chemical America, Inc. consolidates subsidiaries in its One Country, One Company initiative, creating strength and collaboration across businesses.

ALPOLIC received the President’s Award for Environment and Safety, presented by Mitsubishi Chemical Group.

ALPOLIC is formally recognized as a Virginia STAR Worksite under Virginia’s Occupational Safety and Health (VOSH) Voluntary Protection Programs (VPP), the agency’s highest recognition for excellence in safety and health management systems.

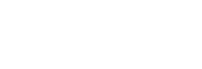

ALPOLIC launches the first series of MCM with a textured surface in the United States.

We’re the Best in the Business

Ideal for Architectural Projects

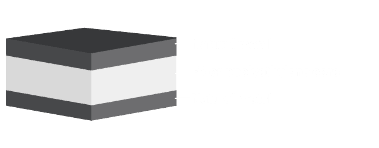

Product Properties

Ease of Fabrication