ALPOLIC Scores with Pro Football Hall of Fame Village

In Canton, Ohio, the birthplace of American football, the Pro Football Hall of Fame faces the same issues of any tourist destination. Namely, how can the organization attract a bigger audience and entice previous visitors to return?

The challenge: improve upon existing venues and design new projects able to withstand anticipated high foot traffic, while meeting tight deadlines to accommodate guests. The solution: durable and easy to install ALPOLIC materials help expand and beautify the village.

Projects: Pro Football Hall of Fame Village, Canton, OH

Architects: DLR Group (Museum Expansion), HKS Architects (Stadium Expansion) and Prime AE (Constellation Center)

Fabricator: Vulcan Metal Sales, Inc.

Installer: Vulcan Metals

General Contractor: Fred Oliveri Construction, Welty (Stadium)

Finishes: ALPOLIC® /fr MBX Medium Bronze, TDR Green, MBU Blue, MCU Mica Champagne, JBR Bronze

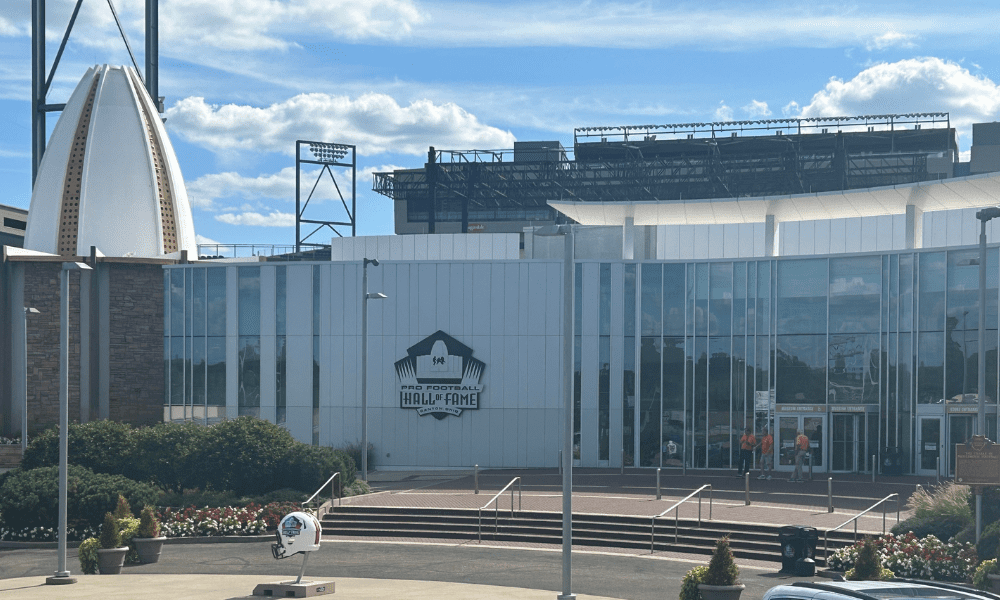

The Professional Football Hall of Fame is more than a museum of artifacts and profiles of inductees. It is a celebration of the sport and a point of inspiration for future professional players. Since opening to the public in 1963, this popular Midwestern destination has seen major expansions of not only the original museum but the surrounding property.

Today, the Pro Football Hall of Fame Village spans 100 acres in Northeast Ohio and includes several venues for team and individual sports, event spaces for public and private functions, and the Fan Engagement Zone entertainment plaza. The most recent expansion of the original museum in 2012-13 saw the addition of ALPOLIC metal composite materials. The architectural firm of Westlake Reed Leskosky, now part of DLR Group, included in their design a new entrance clad with Mica Champagne MCM. The signage attached to the envelope depicts imagery of the original museum, bridging the past to the present.

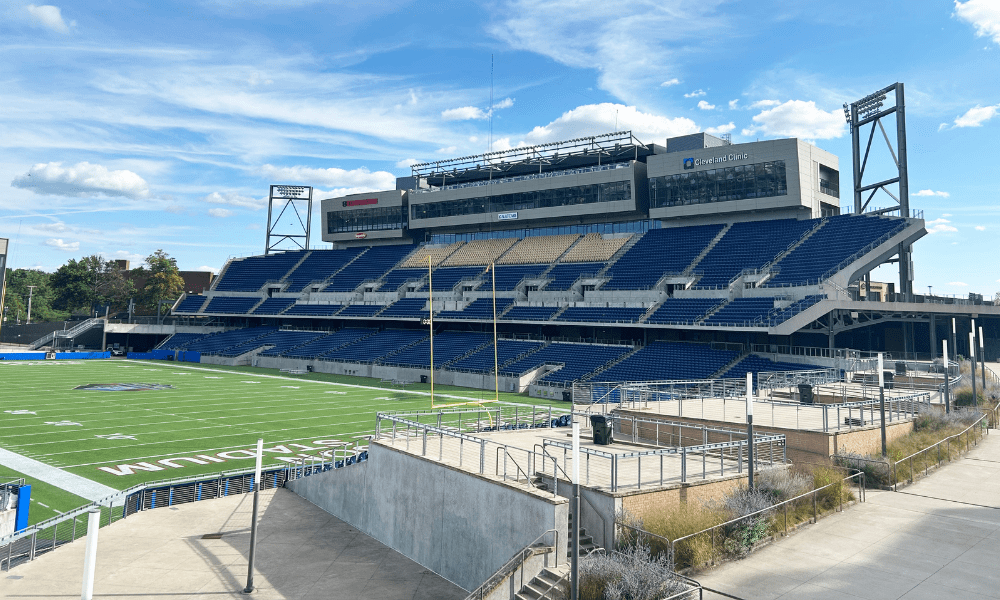

With the growth of the village came the need to improve upon the former Fawcett Stadium, the home field for the annual Hall of Fame Game, which was built in the 1930s. HKS Architects’ design for the renovated venue increased seating from 15,000 to 23,000, with over 35,000 square feet of ALPOLIC Bronze MCM cladding the stadium’s new exterior and NFL-caliber press and VIP boxes. Completed in 2017, the stadium was renamed by a top donor, philanthropist and former New Orleans Saints owner Tom Benson.

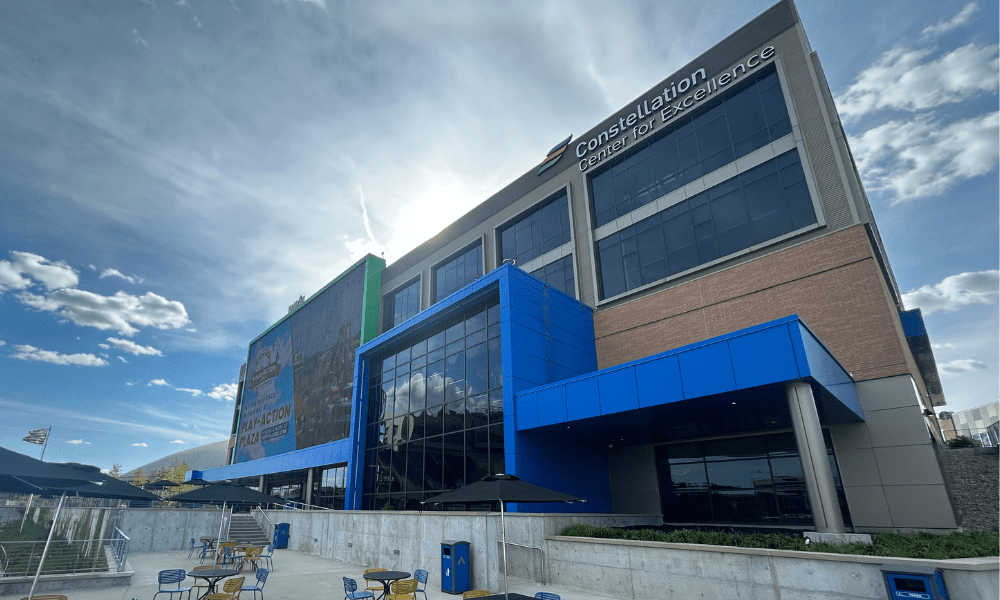

The latest addition to the village is the Constellation Center for Excellence, designed by Prime AE. Completed in 2021, the center provides space for offices, retail, and athletic research and training. Over 33,000 square feet of three colorful ALPOLIC finishes feature on the envelope. MBU Blue wraps around much of the building on the fascia and clads the main entryway. TDR Green frames the large outdoor screen facing the west end of the football stadium. MBX Medium Bronze clads the front columns, window frames and infills throughout the envelope.

Choosing the Right Materials

Vulcan Metals Sales, Inc. handled fabrication for several projects in the village, including the ALPOLIC finishes for the stadium and Constellation Center. For the latter project, various factors including tight deadlines and cost led to a change in plans during construction. “The actual design initially was aluminum plate wall panels,” said Kevin Kolano, District Sales Manager at Vulcan Metals Sales, Inc. Where fabricating plate would have taken the project longer to complete, a switch to metal composite materials better suited the Hall of Fame’s timetable.

“I could have a panel of ACM tomorrow, and with plate it could be at least six weeks,” Kolano added with regards to fabrication lead times. He also cited the company’s good relationship with their ALPOLIC sales manager, Chris Alvares, as the deciding factor in which materials to use. “It was an extremely fast-paced project. He was willing to work with us here.”

Approximately 208,000 people visited the Pro Football Hall of Fame Village in 2023, and the organization hopes to increase numbers going forward. The inclusion of ALPOLIC throughout the grounds helps the buildings withstand heavy foot traffic, and ease of maintenance keeps the attractions looking fresh and new in peak tourist season.

Composite Or Plate?

Aluminum walls offer high performance, sustainability, and affordable solutions to projects of any scale, but which material works best? Composite and plate options offer different advantages, which are explored in ALPOLIC’s flipbook, Exploring the Painted Aluminum Panel Options of Composite and Plate.

When you require a limitless color palette, fire safety considerations and an unbeatable warranty, however, ALPOLIC stands above the rest.

Contact the ALPOLIC sales representative in your region to learn more about our products and how our available stock colors and ease of fabrication can bring your project to life on time.